What is Anodized Aluminum? Things to know about Anodized aluminum

- 08-01-2022 10:15:42

- 136

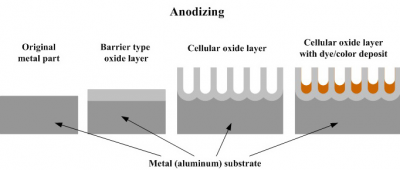

Anodized aluminum is a very high-grade aluminum line formed after the aluminum surface is treated by anodizing technology. This is an oxidation technology by immediately dipping ordinary aluminum sheet. This is also seen as an anode directly into the anodized tank.

The process for surface treatment of aluminum anode is also known as anodizing process. It is understood as electrolysis of Anodes. Unlike other metals, this oxidation does not weaken the bonds of aluminum. On the contrary, it creates a very hard surface coating with a thickness of: 10 - 12 Micrometers. The procedure for surface treatment is carried out sequentially in the following steps:

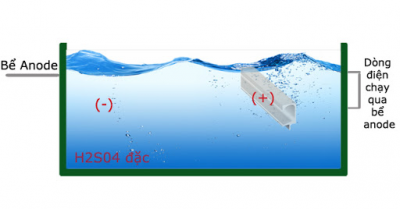

Step 1: Aluminum bar will be put into anodized tank. It contains very concentrated sulfuric acid chemical.

Step 2: In this oxidizing environment, the aluminum bar is considered the anode and the chemical tanks will be the cathode.

Step 3: Let direct current flow through the Anodize tank to oxidize the aluminum surface. It then forms a coating on the thin, yet super-strong aluminum. This is the way to create a protective layer for aluminum bars. From there, aluminum helps to resist corrosion, rust and is resistant to the effects of weather.

News other

-

How many types of solar inverters are there?

10-01-2022 17:15:06 Details

-

Install a solar battery system properly

10-01-2022 16:25:02 Details

-

The Vietnam Renewable Energy Community organizes a Caravan journey towards the Central region

10-01-2022 09:12:28 Details

-

Solar panel system rotates in the direction of the sun – Up to 30% higher efficiency

10-01-2022 09:11:15 Details

-

Why is solar power in the Central Highlands extremely ”hot” in 2020?

10-01-2022 09:04:02 Details

-

What are solar lights?

10-01-2022 09:01:07 Details